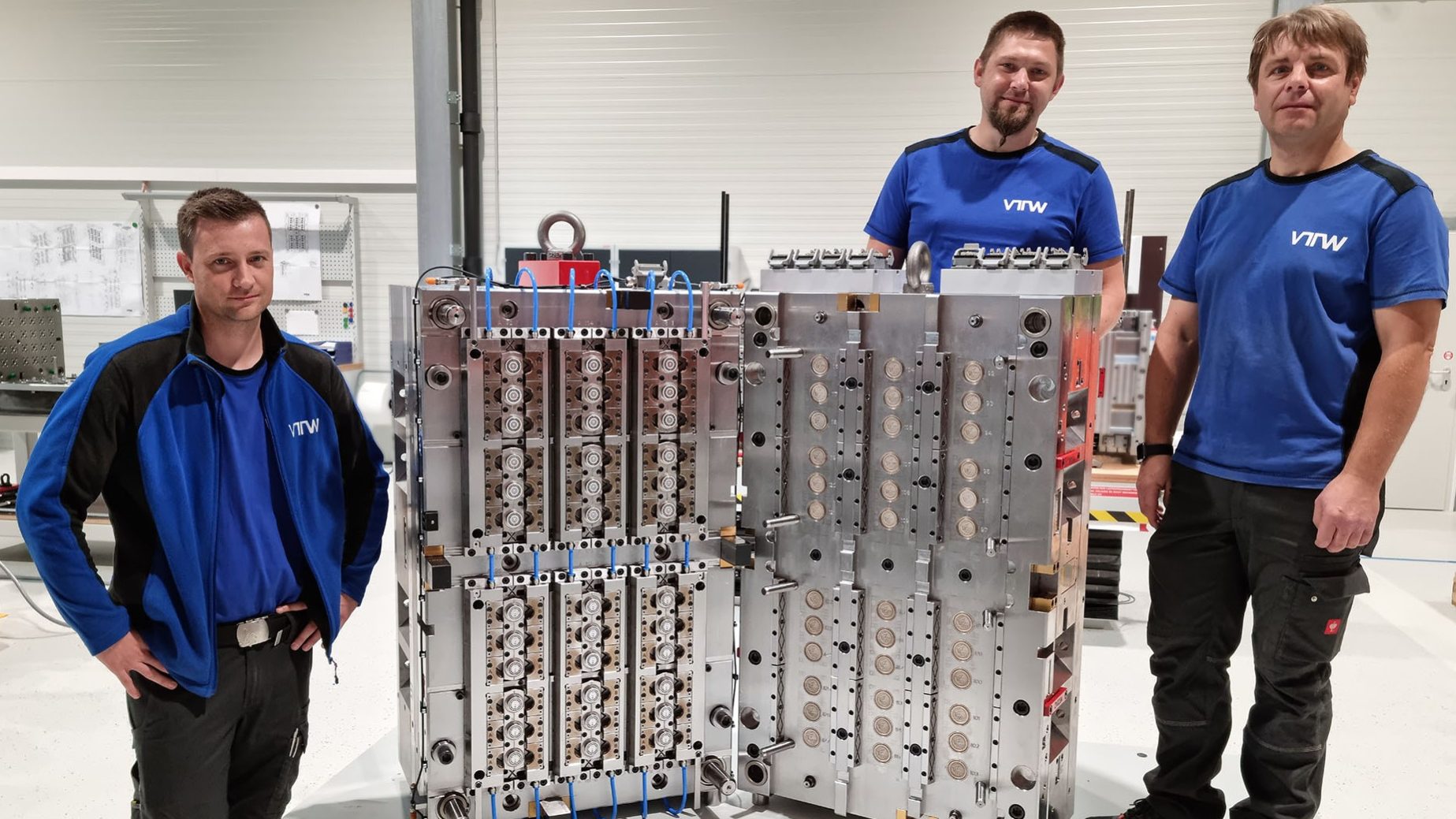

The know-how of the experienced employees combined with the precision of the state-of-the-art machinery made the commissioning of one of the first moulds completely manufactured in the new VTW plant a complete success. The closure for effervescent tablets impresses with multifunctional performance and outstanding quality. “Only the smooth interaction of design with production during the production of the 36-cavity mould made this outstanding performance possible, which ensures a seamless transition to the next process step – the measurement and validation of the article,” emphasizes project manager Johannes Winkelbauer.

The project is not only a success in technical terms, but also in terms of delivery time. Thanks to forward-looking capacity planning and detailed scheduling of the individual process steps, the injection mould was ready precisely on the promised delivery date.

Right in the middle of the action is Reinhard Christian, a proud member of the VTW team since October 1, 2021. In the assembly, he is actively involved in assembling the individual mould components. Reinhard Christian can look back on 25 years of professional experience in toolmaking and has demonstrated his flair for complex technical requirements and his know-how by earning the title of master craftsman. In the future, he will pass on this knowledge to the next generation of plastic moulders and mouldmaking technicians as an apprentice trainer. If you too would like to give ideas the right shape, send your application to jobs@vtw.co, because we will be happy to welcome those interested to join us from October 2021. You will not only benefit from state-of-the-art machinery and optimal working conditions, but also from the latest technologies, the concentrated know-how of our experts and an incomparable team spirit!